While freshening up up the valve cover gaskets (leaking) and vacuum hoses (dried and cracked). I decided to make some new teflon gaskets to help keep some heat out of intake manifold. While this isn’t a race car, i’ll take any extra HP/MPG i can get!

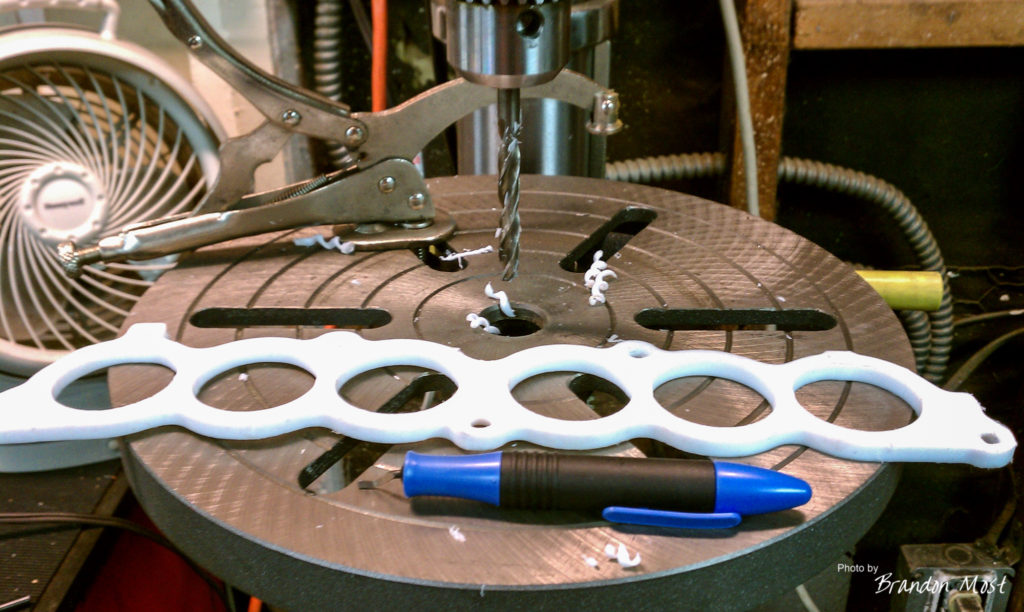

anyway …. here’s a couple pics of the process:

I only had some thick (1/4″) material for the intake manifold, so as a consequence i had to machine the bolt hole (into a slot) in the brace that runs from the cylinder head to the upper plenum, other than that it worked great even with the stock hardware.

For the throttle body i used thinner 1/8″ material. It was important to keep the throttle body separated from the intake because i didn’t want to bypass the coolant from the throttle body. Of course as a “side effect” i got a round gasket for the throttle body as well!